What We Do

Machining:

Our Machine Shop is equipped with all basic machine tools such as Lathes, shapers & millings machines as well as Grinders, pipe & stud threading machine& Drilling machines vertical & Horizontal, boring machines etc….. Our Machine Shop is capable for all kind of Machining & Repair works such as- All type of Turning, boring, machining & maintenance works & part repair

- helical gears, Worm gear, Worm shafts, bevel gear

- Cylinder Boring, Head Facing, Engine Re-Conditioning etc

LIST OF MACHINERY IN OUR WORKSHOP & EQUIPMENT:

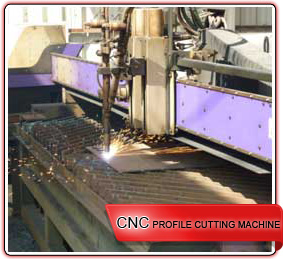

- SIZE : 3 METER TO 12 METER TABLE SIZE

- CAPACITY 12 MM THK. PLASMA FOR STAINLESS STEEL & 50 MM THK. FOR C.STEEL

A-Fabrication Division

- Shearing Machines ( 12mm x 3 mt & 16 mm x 2.5 mt

- Rolling Machines from( 1 mm to 20mm x 2 mt )

- Section shearing Machines(Band saws)up to Ø650 mm

- Pipe Bending Machines up to 7” Dia

- Welding Machines – ARC, MIG (CO& TIG(Argon)

- Welding Generators

- Hydraulic Press from 100 Ton to 300 Tons

- Punching Machine from 35 Ton to 120 tons

- Drilling Machine from 1 mm to 75 mm

- Plasma Cutting Machines (SS up to 1’)

- CNC Plasma(oxy acetylene)Cutting Machine (3x12mts)

- Lathe 10’ Long Max & Swing 1.3mtr.

- Vertical Lathe Ø 1.2m

- Vertical Lathe 16 Feet Ø 1.5 m

- Drilling Machine Max.Capacity Ø 3”

- Boring Machine for Overhauling of vehicle engine

- Milling Machine (vertical & horizontal)

- Drilling Machine small & Big

- Crank Shaft Grinding Machine (3.5 Mt Long)

- Honing Machine

- Surface Grinder – 500 x 3 Meter

- Hydraulic Press up to 300 ton

- Horizontal Boring Machine

- Vertical Boring Machine

- Pipe & stud Threading Machine (up to 4” Dia)

Fabrication:

We specialize in fabricator manufacturings which have better quality standards. Al Fatth serves mechanical fabrication to the following industries.1) gas & oil field 2) power plants 3) water treatment etc.As part of fabricator industry we are specialized in the following works.- Piping – carbon steel, stainless steel, ductile iron, copper nickel etc..

- Steel structure, platforms, sheds, walk ways & handrails

- Steel tanks for storage of fuel, chemical & water.

- Cement silos, transit mixers & mixing tanks

- Skid mounting of plant equipment & fire fighting systems

- All type of casting in copper, bronze, cast iron/ aluminium & machining work.

- Pressure vessels for chemical & food processing

Welding:

Al Fatth employs considerable experience qualified & certified welders. Welding disciplines includes MIG, TIG, SAW, and FLUX CORE & STICK Welding. Not only of steel, but Aluminium, stainless steel, carbon steel & impact materials.Blasting & Painting:

In line with our commitment to the environment, we are doing Blasting using only the highest quality steel Grit in two enclosed sheds (9 x 6 mts) We are doing our painting & blasting jobs with experienced people in the related field. Our range of specialized services- Industrial painting

- Structural steel painting

- Protective coating

- Grit blasting with recovery system